Services

P+N Foran Engineering Limited offer multiple services for our clients to choose from such as fabrication & welding, all carried out by qualified professionals.

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

Off-Site Fabrication

Off-site fabrication is a process that incorporates prefabrication and pre-assembly. The process involves the design and manufacture of units or modules, usually remote from the work site, and the installation at the site to form the permanent works at the site. In its fullest sense, off-site fabrication requires a project strategy that will change the orientation of the project process from construction to manufacture to installation.

On-Site Fabrication

At P+N Foran Engineering Limited we offer onsite fabrication, this can cover a wide variety of works, such as the welding of plates onto existing members to allow new members to be installed.

Onsite Fabrication can save a lot of time and money when it comes to transportation to a factory to be fabricated then back to the site to be re-installed.

Pipe Fitting

Pipe fitters plan and test piping and tubing layouts (cut, bend or fabricate pipe or tubing segments) and join those segments by threading them, using lead joints, welding, brazing, cementing, or soldering them together. They install manual, pneumatic, hydraulic and electric valves in pipes to control the flow through the pipes or tubes. These workers create the system of tubes in boilers and make holes in walls and bulkheads to accommodate the passage of the pipes they install.

Suppling Skilled Workers

At P+N Foran Engineering Limited we can supply your company with fully-qualified professionals from Ireland and Europe to meet all of your fabrication, welding and pipe fitting needs. Visit the Contact Us page today and find out more about this fantastic service we can offer you!

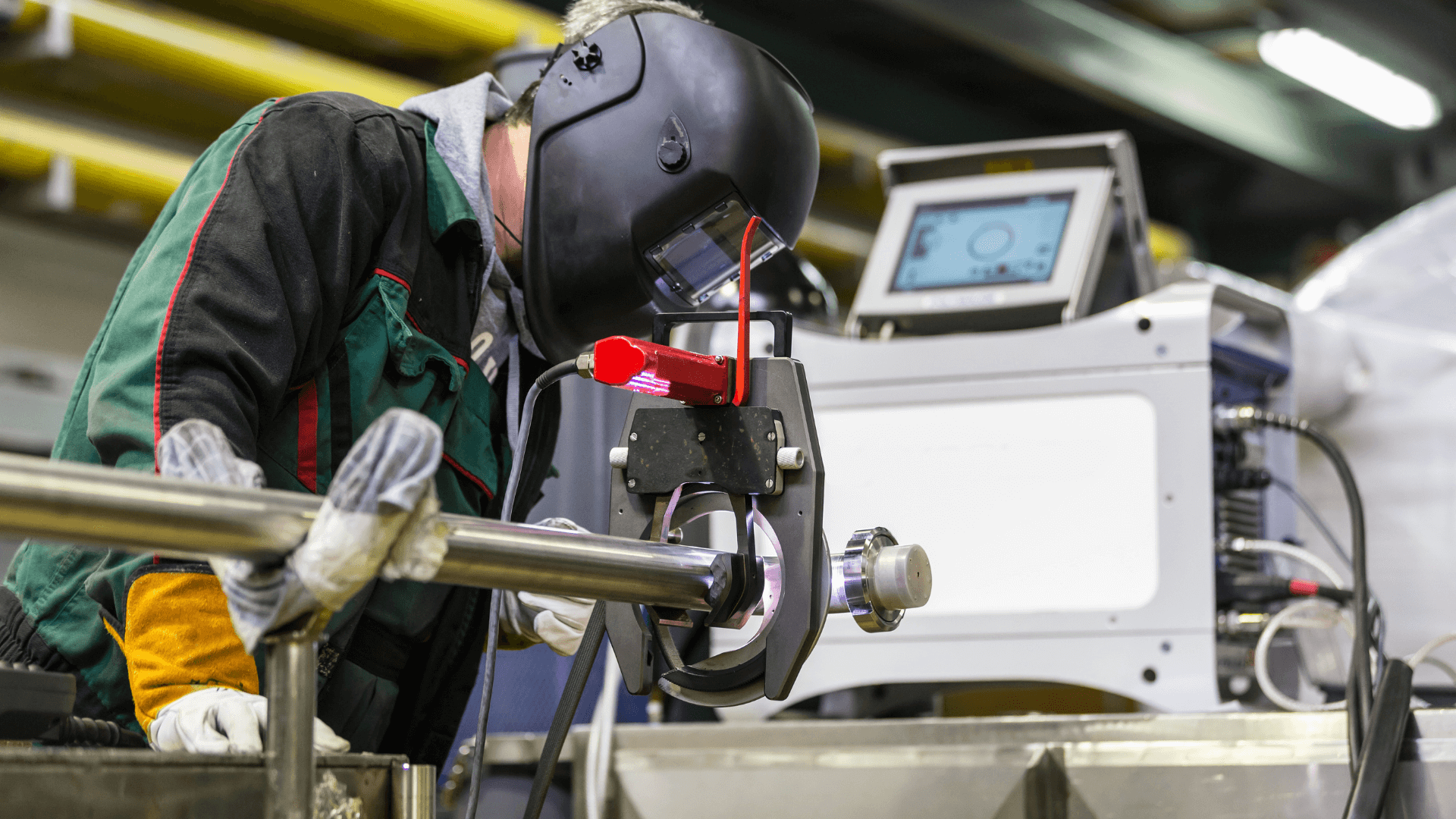

Orbital Welding

This is a specialized area of welding whereby the arc is rotated mechanically through 360° (180 degrees in double up welding) around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to address the issue of operator error in gas tungsten arc welding processes (GTAW), to support uniform welding around a pipe that would be significantly more difficult using a manual welding process, and to ensure high quality repeatable welds that would meet the European Union welding standards. In orbital welding, computer-controlled process runs with little intervention from the operator.